Conservation of Resources

Conservation and protection of resources is a matter of course for us. Sustainable planning and sustainable use of raw materials is a priority for us: with special Business Excellence projects for yield optimization and material efficiency. With well thought out concepts for waste management and recycling. And with special product solutions based on renewable and CO2 based polyols.

Waste and recycling concepts

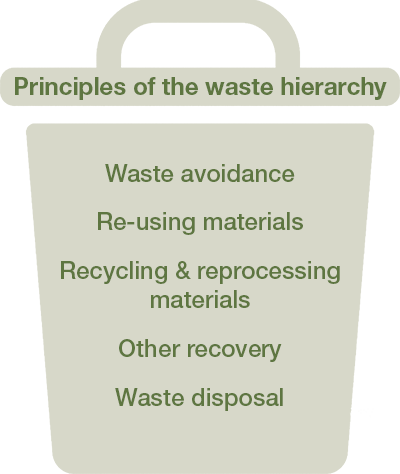

Waste management and recycling are of particular importance to FoamPartner, especially with regard to sustainability aspects. We always have different forms of energy, the environment, and resources in mind. And we act accordingly:

- We avoid waste before it is produced in order to conserve resources. For example, through demand oriented production with optimized material yield.

- We use foams repeatedly if possible. For example, through the targeted further processing of residual blocks and larger cutting residues.

- We use materials that can be recycled or reconditioned, for example to recycled polyols or ground PUR powder.

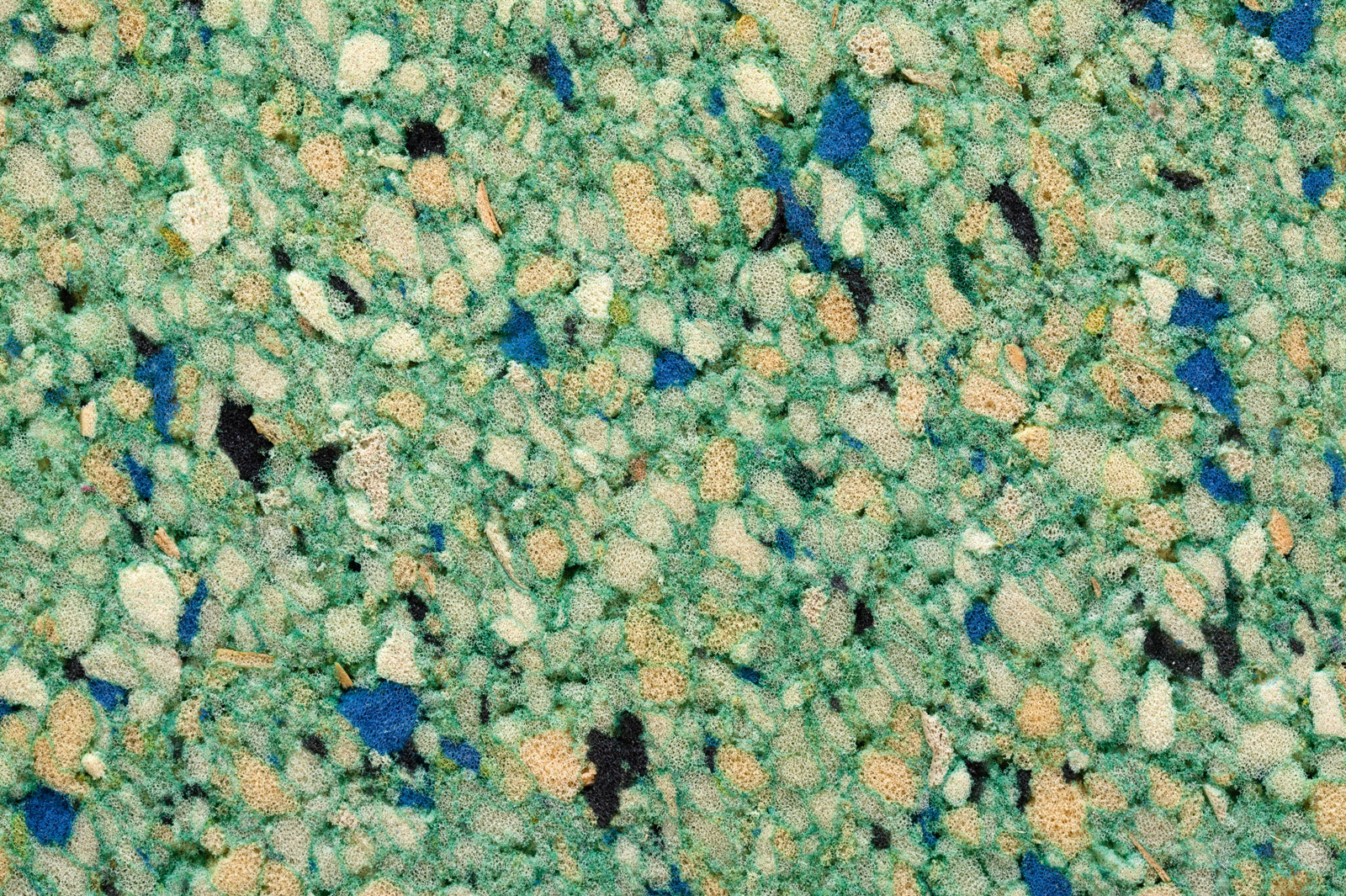

- We separate waste and recycle small cutting residues in accordance with the corresponding value streams. For example, to produce composite foams.

- We ensure energy recovery before disposal. For example, through the thermal recycling of used mattresses.

Advanced recycling initiatives

The chemical recycling of foams to obtain polyol has been known in the technical literature for several years. The topic has gained interest, especially in recent times, and we assume that the economic breakthrough here will not be long in coming. We are prepared for this: In various tests we have combined recycled and fresh polyol for new mattress foams. Our results show that up to 20 % of the recycled polyol could be reused in a new foam.

Recycled, ground PUR powder can be used as filler for new foams. A proportion of 10 – 15 % has no effect on the properties of new foams. FoamPartner already uses this method in the production of a household sponge.

Chemical recycling

1. PUR foams are produced in the foaming plant. The raw materials used are mainly polyols and reactive isocyanates. The polyol component can consist of 1 part recycled sources and 4 parts “virgin” sources.

2. The foam blocks are further processed e.g. to mattresses. Cutting residues occur during conversion. Foam residues can be processed. They are either processed as composite foam or sent for chemical recycling.

3. The process for the chemical recycling of PUR foams is called acidolysis. To obtain recycled polyol, the same percentage of foam residues and “virgin” polyol is used.

Resources of the future

Sustainable raw materials are another topic that we deal with intensively. We are constantly looking for new ways to use polyols on a renewable basis in our foams. Their use in production is not a problem. However, we exclude some raw materials due to ethical concerns, such as palm oil based polyols.

Currently, we use polyols based on CO2, cashew nutshell, castor, rapeseed and sunflower oil for applications in the Mobility and Specialties segments. In principle, such polyols can be used in a concentration of up to 100 %, depending on the area of application. The sustainable proportion in the finished foam is then a maximum of 60 %. We are working on various projects to continuously increase the use of sustainable raw materials.

Less is more – material efficient working

Our plant in Wolfhausen, like all our sites, operates according to the motto: No overproduction! Production and delivery are always adapted to customer requirements and order situations. Since 2017 we have established a special waste management system here.

Residual blocks are processed in a targeted manner, unused blocks are collected and stored. With every new customer order, the existing residual blocks are checked for use and, if appropriate, processed.

The tops, which used to be simply disposed of, are now partly processed further into rolls which are used as technical foam, for example in packaging. Dome remains and edges are separated, sorted by foam type and reused as composite foam.

This procedure enables targeted processing while at the same time making efficient use of the material. It reduced waste at the Wolfhausen site by 6 % in just one year and we want to achieve even more. Our current Business Excellence project “Big Move” to increase earnings, includes many new approaches and ideas for waste avoidance, and the team is working hard to implement them.

Read more in the next section

-

Climate Protection

Sustainability - Planet

Climate protection and energy efficiency go hand in hand at FoamPartner. Here, we focus primarily on reducing CO2 emissions. And general savings measures such as new mobility concepts and travel guidelines, we make every step count.