CARPENTER announces acquisition of

Recticel Engineered Foams Division

(formerly FoamPartner)

Headliners

First-class Foams for the Automotive Industry – up to 50% fewer bonded seams thanks to a unique 120 m long block foam technology

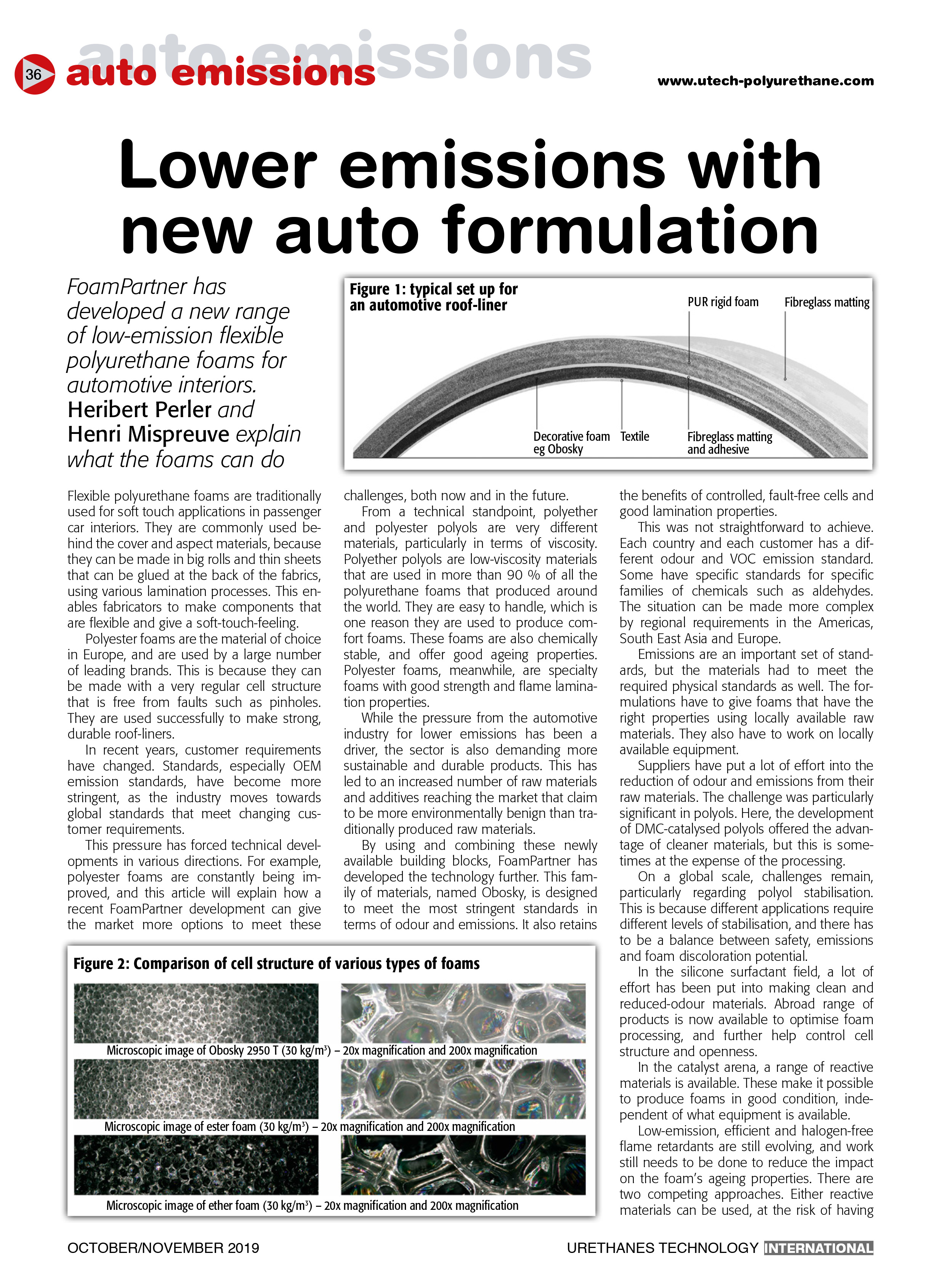

Major automotive suppliers worldwide trust in our 60 years of market experience and choose our decorative foams for their headliners. They are especially easy to work with, for instance using flame bonding and adhesive lamination. In addition, they are hydrolysis stable and impress with high elasticity and long service life, an even, homogeneous cell structure and good thermoformability. They have low VOC and fogging values, and are extremely low-odor and low-emission.

Our unique 120m long block technology results in up to 50% fewer bonded seams than competitors’ products. Our solutions for interior headliners are adapted and produced specifically to meet your needs, with Ether and Ester-based polyurethane foams or a new, ether-based prepolymer technology. We design the technical properties based on your requirements.

NEW: Ether-based prepolymer for innovative roof liners

OBoSky® is the solution for modern roof liners: regular surfaces, soft-touch feeling & an improved interior climate impress consumers – car manufacturers benefit from simple processing, durability & efficient use of materials.

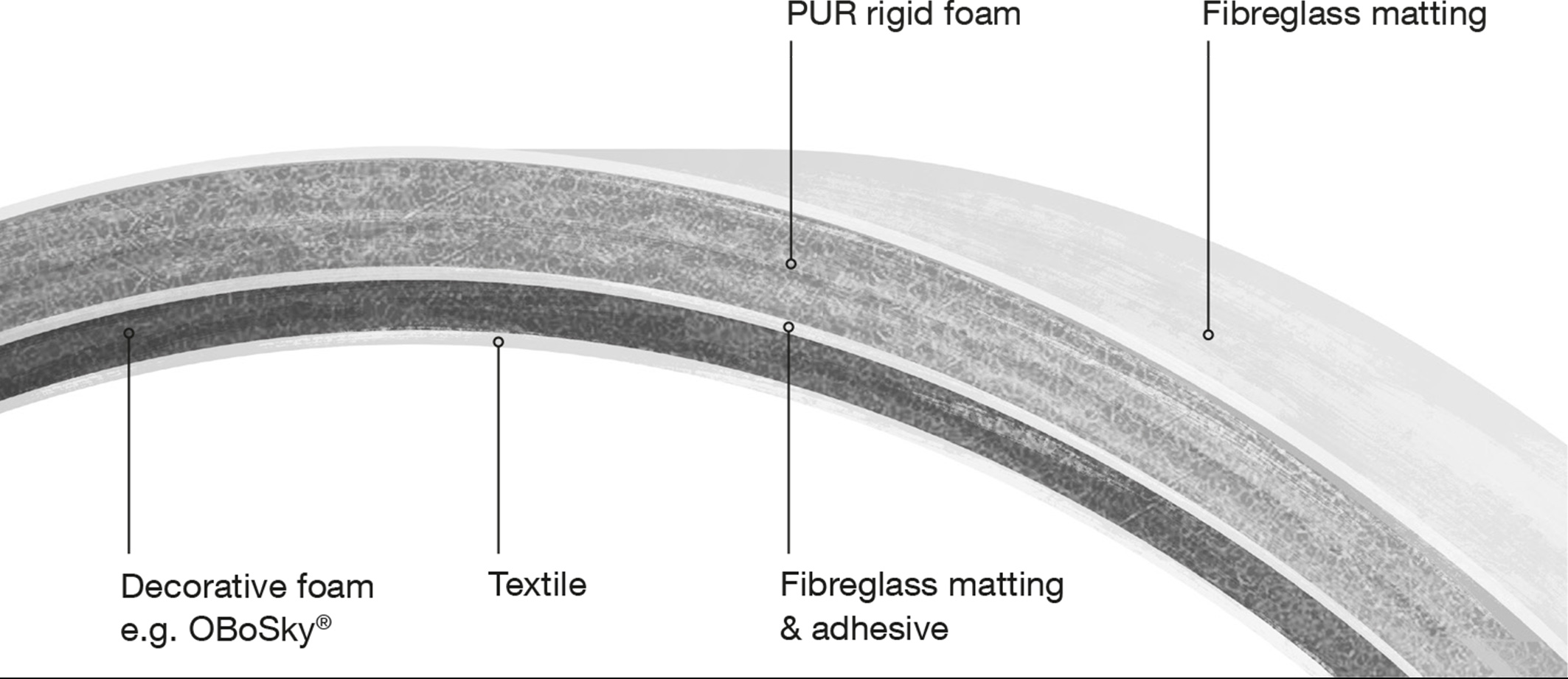

Vehicle Component Headliners

Advantages & Customer Benefits

Up to 50% fewer bonded seams than competitor products thanks to our unique 120m long block technology.

Low VOC and low fogging properties, making them especially low-odor and low-emission.

Available worldwide as a roll good in Europe, Asia and the USA.

Properties – Interior Components Headliner

PUR Polyester

- especially easy to work with

- very well suited for flame bonding and adhesive lamination

- high elasticity

- homogeneous cell structure for homogeneous surfaces

- good thermoformability

PUR Polyether

- low VOC (low percentage of volatile organic compounds)

- low fogging values

- extremely low-emission

- low-odor

- hydrolysis stable and long-lasting

Prepolymers

Our new, patented OBoSky® solution combines the advantages of polyester and polyether-based headliner components.

Technical Data

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Compression set [%] DIN ISO 1856 (50 %, 70°C, 22 h) |

Fogging gravimetric [mg] DIN 75201 - B |

|---|---|---|---|---|---|---|---|

| B 28 BF-LF | Polyester PUR foam | 28 | 4,2 | >140 | >170 | <10 | <1 |

| B 28 FLE-LF | Polyester PUR foam | 28 | 4,5 | >140 | >170 | <10 | <1 |

| B 29 A/F/O-LF | Polyester PUR foam | 29 | 4,0 | >150 | >250 | <20 | <1 |

| B 35 A/GP-LF | Polyester PUR foam | 35 | 4,5 | >150 | >200 | <10 | <1 |

| B 35 BLE-LF | Polyester PUR foam | 35 | 4,5 | >170 | >200 | <10 | <1 |

| B 35 FLE-LF | Polyester PUR foam | 35 | 4,5 | >170 | >200 | <10 | <1 |

| B 42 BLE-LF | Polyester PUR foam | 42 | 5,0 | >150 | >220 | <10 | <1 |

| B 42 FLE-LF | Polyester PUR foam | 42 | 5,0 | >150 | >220 | <7 | <1 |

| B 42 GP-LF | Polyester PUR foam | 42 | 4,5 | >150 | >220 | <10 | <1 |

| B 46 BLE-LF | Polyester PUR foam | 46 | 5,0 | >120 | >160 | <10 | <1 |

| B 48 N-LF | Polyester PUR foam | 48 | 5,5 | >150 | >200 | <5 | <1 |

| B 50 N-LF | Polyester PUR foam | 50 | 5,5 | >150 | >200 | <5 | <1 |

| B 52 A-LF | Polyester PUR foam | 52 | 6,0 | >150 | >300 | <5 | <1 |

| B 55 A-LF | Polyester PUR foam | 55 | 6,0 | >150 | >220 | <5 | <1 |

| B 55 N-LF | Polyester PUR foam | 55 | 5,5 | >150 | >200 | <5 | <1 |

| OboSky 2950 T Basic | Prepolymer polyether PUR foam |

29 | 5,0 | >90 | >130 | <7 | <1 |

| Obosky 2950 T | Prepolymer polyether PUR foam |

29 | 4,0 | >90 | >130 | <7 | <1 |

| OBoSky 2950 C ** | Prepolymer polyether PUR foam |

30 | 4,0 | >90 | >130 | <7 | <1 |

| OBoSky 3540 T | Prepolymer polyether PUR foam |

35 | 4,0 | >90 | >150 | <6 | <1 |

| OBoSky Nature 3540 T | Prepolymer polyether PUR foam |

35 | 4,5 | >110 | >200 | <6 | <1 |

| OBoSky 4248 T | Prepolymer polyether PUR foam |

42 | 4,8 | >90 | >150 | <7 | <1 |

| OBoSky 4270 T | Prepolymer polyether PUR foam |

42 | 7,0 | >150 | >100 | <7 | <1 |

Other volume weights available on request.

* The indicated data refer to typical values and slight variations are in general within the specification.

Please consult your local sales representative at FoamPartner to obtain the actual product data sheet with the latest technical product details.

** Production Changzhou, China