CARPENTER announces acquisition of

Recticel Engineered Foams Division

(formerly FoamPartner)

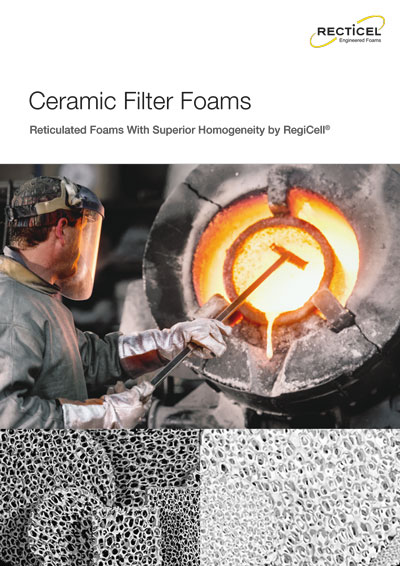

Ceramic Foam Filter

Leading manufacturer for ceramic foam filters

Our foams for ceramic filters meet the highest quality standards and provide outstanding homogeneity. They are available in numerous pore sizes and are used in ceramic filters for all common metals, such as iron, stainless steel and aluminum.

In our role as a leading manufacturer of ceramic filter foams, we have a deep understanding of our customers' needs as well as industrial requirements. With the highest quality standards, we ensure the extraordinary homogeneity of our filter foams and thus achieve maximum effectiveness for the final product. All of our products feature an exceptionally homogeneous foam structure, and offer solid wetting and recovery properties.

Various Pore Sizes – For All Applications

We offer one of the widest portfolios of PUR foams on the market, and produce polyurethane foams in a wide variety of pore sizes. Our pore sizes from 7 to 50 ppi allow our customers to produce ceramic filters for all common metals and alloys, including iron, stainless steel and aluminum.

Tightest Tolerances – For Absolute Reliability

We set the smallest tolerances for the pore sizes to ensure the reliability of the final product. When you rely on our foams for ceramic filters, you benefit from excellent wettability and adhesion, optimized geometric stability, and outstanding recovery after impregnation.

Product Highlights – For Important Applications

For stainless steel ceramic filters, we recommend our foam RegiCell 7FM2. For use on aluminum, our RegiCell 15-25 is ideal, and RegiCell 10 FM2 is the suitable model for iron ceramic filters.

Due to its positive air flow properties, RegiCell 60 has proven itself particularly well suited for use in air filters.

Advantages & Customer Benefits

Delivery Forms

Blocks, sheets, and pre-cut filters.

Technical Data

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Pores per inch REGI RPA-1002 |

|---|---|---|---|---|---|---|

| RegiCell 7 FM 2 for stainless steel ceramic filters |

Polyester PUR foam | 27 | 4,5 | >90 | >80 | 7 |

| RegiCell 8 FM 2 for stainless steel ceramic filters |

Polyester PUR foam | 27 | 4,5 | >110 | >100 | 9 |

| RegiCell 10 FM 2 for iron ceramic filters |

Polyester PUR foam | 30 | 4,5 | >110 | >100 | 10 |

| RegiCell 13 FM 4 for iron ceramic filters |

Polyester PUR foam | 30 | 4,5 | >110 | >100 | 13 |

| RegiCell 15 FM 4 for iron/aluminum ceramic filters |

Polyester PUR foam | 30 | 4,7 | >100 | >120 | 16 |

| RegiCell 20 FM 4 for aluminum ceramic filters |

Polyester PUR foam | 30 | >3,8 | >100 | >120 | 19 |

| RegiCell 25 FM 4 for aluminum ceramic filters |

Polyester PUR foam | 30 | >3,8 | >100 | >120 | 23 |

| RegiCell 30 FM 4 for aluminum ceramic filters |

Polyester PUR foam | 30 | >3,8 | >100 | >120 | 30 |

| RegiCell 40 GA for aluminum ceramic filters |

Polyester PUR foam | 30 | 4,0 | >120 | >120 | 37 |

| RegiCell 50 GA for aluminum ceramic filters |

Polyester PUR foam | 30 | 4,0 | >150 | >120 | 48 |

* Die angegebenen Daten beziehen sich auf typische Werte, leichte Abweichungen liegen im Allgemeinen innerhalb der Spezifikation.

Bitte wenden Sie sich an Ihren lokalen Verkaufsberater bei FoamPartner für das entsprechende Produktdatenblatt mit den neuesten technischen Produktdetails.