CARPENTER announces acquisition of

Recticel Engineered Foams Division

(formerly FoamPartner)

Expertise in Acoustic and Thermal Management

We are a flexible contact partner with extensive competence in the area of lightweight customized solutions for acoustically and thermally challenging environments.

FoamPartner develops and manufactures acoustically and thermally effective components and systems for your individual needs in especially challenging environments. If you need ultralight customized solutions for your special applications, we work with renowned partners from various industries to give you reliable support, with customer-specific materials and an impregnation option. Through our modern acoustics center, FoamPartner gives you access to our comprehensive knowledge about sound absorption and noise protection. Our in-house development, which includes R&D, prototype building, 3D/2D modeling as well as tool construction and manufacturing, ensures that our solutions are constantly further developed based on your requirements.

Our emphases: vehicle acoustics, headliners and seals. In these areas, FoamPartner uses foams as a functional high-tech material for cars, heavy trucks, aerospace, trains, streetcars, ships and more. Our technical foams let you create a customized, function-based design. They meet the standards for lightweight construction and provide optional flame protection.

As a foam manufacturer, we meet the industry’s high quality standards and guarantee you absolute delivery reliability and timeliness.

Acoustic & Thermal Solutions

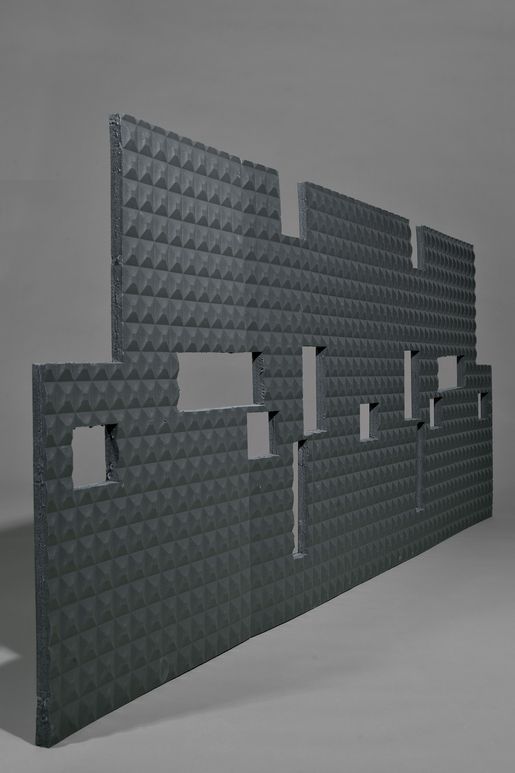

Resonant, not noisy: acoustics

FoamPartner’s targeted acoustics solutions provide excellent acoustics and uncompromising sound quality inside your vehicle. To eliminate noise and sounds in the engine compartment, transmission tunnel and bulkhead as well, you need perfect acoustic services. FoamPartner foams for acoustic solutions in vehicle construction meet all of your needs in reducing annoying noise levels according to your wishes, and they:

- are low-emission

- are thermoformable

- can be laminated

Customer-specific and solution-oriented: the acoustic center

FoamPartner’s acoustic center offers you one-of-a-kind testing options and a wide range of expert knowledge – the service can be used by all FoamPartner customers. We work for and with you to develop possible solutions for acoustic insulations, and develop effective acoustic components that are tailored to your specific needs.

Lightweight and safe: sealing solutions made from lightweight foam

For your applications made from foam that are “dense in function” and “light in assembly,” FoamPartner develops and produces fine-pored, reliable and low-emission materials that improve safety. Their most important features:

- Compressible and easily workable

- Low density

- Low-emission and with minimal odor

E-Mobility: into the future with electric power

Whether it is for meeting climate goals or consumer wishes, e-mobility will be playing an increasingly important role in the next few years. The increased networking of electric means of transport will also present you with countless new prospects, opportunities and questions.

As a specialist in acoustic and thermal solutions and a system supplier, we work with you to face the challenges of electromobility. We are your partner and expert point of contact, and we are already working to find the best solution for your future requirements.

Lightweight and sturdy: headliners

The semi-rigid foams used in vehicle interiors are low-emission and lightweight. They are excellent for processing, which allows them to be used easily for developing customer-specific solutions that are especially tailored to your needs. A few other impressive properties of these foam products:

- High inherent stability – keeps its shape

- Optimal acoustic absorption behavior

- Thermoformable

Sound & Heat Insulation – Application Examples

Applications

Aerospace

Aerospace

Aerospace

Aerospace

- acoustic & thermal insulations

- aircon insulations

- bottom insulations

- floor insulation

- primary insulations

- sealing solutions

- secondary insulations

Aerospace

Aerospace

- acoustic & thermal insulations

- aircon insulations

- bottom insulations

- floor insulation

- primary insulations

- sealing solutions

- secondary insulations

Automotive

Automotive

Automotive

Automotive

- absorber for engine design cover

- absorber for side panel aggregates

- acoustic air flow

- acoustic fleece wheel arch & underbody

- air channel insulations

- air duct acoustic capsule

- air flow absorber

- bottom insulations

- central armrest padding

- convertible top insulations

- cowl insulationstop seal

- cushion for battery box cover

- cushions and cores

- dash insulation parts

- dash insulations

- door insulationdeadening

- door mirror seal

- engine bay absorber

- engine baysound absorber

- engine seals

- fleece absorber

- headliner (lining materials)

- heat protection

- insulation

- insulation dampenings

- luggage compartment

- mirror reinforcement

- pump insulations

- seal for speaker box

- seal for weather-strip joint

- side panels

- suction pipe insulations

- wheel-arch absorber

- wheel-arch damping

- window seals for weather-strip joint

Automotive

Automotive

- absorber for engine design cover

- absorber for side panel aggregates

- acoustic air flow

- acoustic fleece wheel arch & underbody

- air channel insulations

- air duct acoustic capsule

- air flow absorber

- bottom insulations

- central armrest padding

- convertible top insulations

- cowl insulationstop seal

- cushion for battery box cover

- cushions and cores

- dash insulation parts

- dash insulations

- door insulationdeadening

- door mirror seal

- engine bay absorber

- engine baysound absorber

- engine seals

- fleece absorber

- headliner (lining materials)

- heat protection

- insulation

- insulation dampenings

- luggage compartment

- mirror reinforcement

- pump insulations

- seal for speaker box

- seal for weather-strip joint

- side panels

- suction pipe insulations

- wheel-arch absorber

- wheel-arch damping

- window seals for weather-strip joint

Marine

Marine

Marine

Marine

- acoustic & thermal insulations

- air channelpipe & tube insulations

- bottom insulations

- motor room & engine sealing

- pump insulations

- sealing solutions

- side panels

Marine

Marine

- acoustic & thermal insulations

- air channelpipe & tube insulations

- bottom insulations

- motor room & engine sealing

- pump insulations

- sealing solutions

- side panels

Rail vehicles

Rail vehicles

Rail vehicles

Rail vehicles

- acoustic & thermal insulations

- air channel insulations

- bottom insulations

- sealing solutions

- side panels

- wagon insulationsdampenings

Rail vehicles

Rail vehicles

- acoustic & thermal insulations

- air channel insulations

- bottom insulations

- sealing solutions

- side panels

- wagon insulationsdampenings

Advantages & Customer Benefits

In the area of special impregnation, we are happy to give you our advice as experienced experts. Thanks to our extensive experience, we offer you high-tech foam solutions with the following properties:

- Antistatic

- Flame retardant

- Hydrophobic

- Minimal odor

- Moisture-aging resistant

- Self-extinguishing

- Sound-absorbing

- Thermoformable

Our portfolio includes the following types of foam:

- Aerospace acoustic foams (for instance primary and secondary insulations)

- FVMSS-302 foams

- Headliner foams

- Lightweight and semi-rigid foams

- Polyether foams

- Prepolymer foams

- Sealing foams

- Vehicle acoustic foams

Technical Data

Sound absorption and reinforcement for exterior applications

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Burn rate [mm/min] FMVSS 302 |

Compression set [%] DIN ISO 1856 (50 %, 70°C,22 h) |

Colors |

|---|---|---|---|---|---|---|---|---|

| BMB 12 | Melamine foam, hydro- and oleophobic |

13 | >5 (first Cycle) |

>100 | >10 | 0 | non relevant | |

| BMB-10 H | Melamine foam, hydrophobic |

9,5 | >5 (first Cycle) |

>100 | >10 | 0 | non relevant | |

| BMB-10 P | Melamine foam | 9 | >9 (first Cycle) |

>120 | >18 | 0 | non relevant | |

| BMB-6 | Melamine UL | 6 | >3,5 (first Cycle) |

>40 | >10 | 0 | non relevant | |

| BMB-6 H | Melamine, hydrophobic |

6 | >3,5 (first Cycle) |

>40 | >10 | 0 | non relevant | |

| FlexiDur NG | Polyether PUR foam | 14 | >16 (first Cycle) |

>40 | >20 | 0 | non relevant | |

| FlexiDur NGL | Polyether PUR foam | 13 | >16 (first Cycle) |

>40 | >20 | 100 | non relevant | |

| RegiLen 25 X FR | Polyester PUR foam | 25 | >3 | >140 | >200 | <100 | non relevant | |

| RegiLen 28 X FR | Polyester PUR foam | 28 | >4 | >150 | >120 | <100 SE<1 s |

non relevant | |

| RegiLen 30 SVGA | Polyester PUR foam | 27 | >3,5 | >140 | >110 | <100 UL94 mit HF1 |

non relevant |

Sealing foams for exterior applications

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Burn rate [mm/min] FMVSS 302 |

Compression set [%] DIN ISO 1856 (50 %, 70°C,22 h) |

Colors |

|---|---|---|---|---|---|---|---|---|

| RegiSeal Aqua | Prepolymer polyether PUR foams |

32 | >11,0 | >100 | >50 | <100 | <10 | |

| RegiSeal TN 30 FR | Prepolymer polyether PUR foams |

33 | >4,5 | >100 | >130 | <100 | <11 | |

| ReiSeal 50 FR | Polyester PUR foams |

49 | >4,5 | >180 | >170 | <100 | <11 |

Sound absorption and sealing for interior applications

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Burn rate [mm/min] FMVSS 302 |

Compression set [%] DIN ISO 1856 (50 %, 70°C,22 h) |

Colors |

|---|---|---|---|---|---|---|---|---|

| B 75 N-LF | Polyester PUR foam | 75 | >7,5 | >130 | >180 | <100 | < 5 | |

| B2840 FR-LF | Polyether PUR foam | 28 | >6,5 | >80 | >140 | <100 | <10 | |

| B3540 PFK-LF | Polyether PUR foam | 35 | >4,0 | >90 | >150 | <100 | <6 | |

| B42 FLE- LF | Polyester PUR foam | 42 | >5,0 | >150 | >220 | <100 | <7 | |

| RegiSeal Aqua | Prepolymer polyether PUR foams |

32 | >11,0 | >100 | >50 | <100 | <10 | |

| RegiSeal TN 25 FR X | Prepolymer polyether PUR foams |

25 | >3,5 | >100 | >130 | <100 | - | |

| RegiSeal TN 30 FR | Prepolymer polyether PUR foams |

33 | >3,5 | >70 | >105 | <100 | <11 | |

| RegiSeal TN 30 FR X | Prepolymer polyether PUR foams |

33 | >5,0 | >90 | >90 | <100 | <5 |

Reinforcement for interior applications

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Burn rate [mm/min] FMVSS 302 |

Compression set [%] DIN ISO 1856 (50 %, 70°C,22 h) |

Colors |

|---|---|---|---|---|---|---|---|---|

| EvoDur RD 32 | Polyether PUR foam, semi-rigid |

31 | >85 | >220 | >11 | <100 | non relevant | |

| EvoDur RD 37 | Polyether PUR foam, semi-rigid |

33 | >125 | >250 | >10 | non relevant |

Sound absorption with soft touch for interior applications

| Product | Product group | *Density net [kg/m3] DIN EN ISO 845 |

*Compression load [kPa] DIN EN ISO 3386-1 |

Tensile strength [kPa] DIN EN ISO 1798 |

Elongation at break [%] DIN EN ISO 1798 |

Burn rate [mm/min] FMVSS 302 |

Compression set [%] DIN ISO 1856 (50 %, 70°C,22 h) |

Colors |

|---|---|---|---|---|---|---|---|---|

| B55 N-LF | Polyester PUR foam | 55 | >5,5 | >150 | >200 | <100 | non relevant | |

| HyPore 4270 | Prepolymer polyether PUR foams |

42 | >7,0 | >150 | >100 | <100 | non relevant | |

| RegiSeal Aqua | Prepolymer polyether PUR foams |

30 | >8,5 | >100 | >50 | <100 | non relevant | |

| RegiSeal TN 30 FR LF | Prepolymer polyether PUR foams |

33 | >5,0 | >90 | >90 | <100 | non relevant | |

| RegiSeal TN 30 FR X | Prepolymer polyether PUR foams |

33 | >5,0 | >90 | >90 | <100 | non relevant |

* The indicated data refer to typical values and slight variations are in general within the specification.

Please consult your local sales representative at FoamPartner to obtain the actual product data sheet with the latest technical product details.